R & D

At ‘Parag’ Fans, innovation is the dParag Fans R & Driving force behind the Company’s success. Here, R & D is an ongoing process which results in improving and expanding the product lines by developing new and innovative products and manufacturing techniques. The R & D at ‘Parag’ Fans is in association with the Department of Aerospace Engineering, Indian Institute of Technology, Mumbai. It is because of its extensive R & D efforts that the company has been able to tackle some of the most challenging Fan applications including:

- Development of a 4,622mm diameter FRP Fan along with the Nose Spinner for the Department of Aerospace Engineering, Indian Institute of Technology, Mumbai for its National Wind Tunnel Facility Project, a state-of-the-art low speed, closed circuit wind tunnel. The Fan was powered by a 1,000kw motor

- Development of Energy Efficient Axial Flow FRP Fans in association with the Technology Information Forecasting & Assessment Council (TIFAC); Department of Science & Technology (Government of India), New Delhi; and Department of Aerospace Engineering, Indian Institute of Technology, Bombay. Five Fans were designed, developed and tested successfully in the project for the following specific applications

- 1,680 mm diameter Fan for Indian Railways Diesel Locomotive (as per ‘Research, Design & Standards Organization’, Ministry Of Railways, Government Of India specifications).

- 10,000 mm diameter Fan for Cooling Tower (as per ‘BDT’ specifications)

- 4,267 mm diameter Fan for Air Cooled Heat Exchanger (as per ‘Engineers India Ltd.’ specifications).

- 2,000 mm diameter Fan for Mine Ventilation (as per ‘ Western Coalfields Ltd.’ specifications)

- 1,200 mm diameter Fan for Humidification (as per ‘Ahmedabad Textile Industry’s Research Association’ specifications).

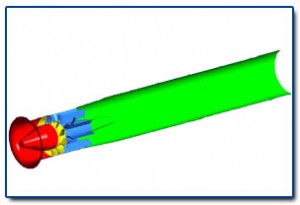

- Development of the unique process to produce a single piece, hollow, FRP blade using Resin Transfer Molding Technology in association with Dr. Franz Haff under the SES program of Government of Germany.

- Development of a High Efficiency Reversible FRP Fan under the technical guidance of Mr. Heinz Andritzky, a SES expert from Germany.

Development of Energy Efficient Axial Flow FRP Fan System in association with the Department of Scientific & Industrial Research (Government Of India) New Delhi and Ahmedabad Textile Industry’s Research Association, Ahmedabad

Development Of Energy Efficient Axial Flow FRP Rotor for Mine Ventilation for M&I Mining Group, Canada. The Rotor provided reduction of motor rating from 75 HP to 40 HP.